Not known Facts About Motorcycle Parts New Zealand Specialists

Wiki Article

The 9-Second Trick For Motorcycle Parts New Zealand Specialists

Table of ContentsThe Best Strategy To Use For Motorcycle Parts New Zealand SpecialistsThe 25-Second Trick For Motorcycle Parts New Zealand SpecialistsThe Main Principles Of Motorcycle Parts New Zealand Specialists Some Ideas on Motorcycle Parts New Zealand Specialists You Should KnowEverything about Motorcycle Parts New Zealand SpecialistsThe Ultimate Guide To Motorcycle Parts New Zealand SpecialistsHow Motorcycle Parts New Zealand Specialists can Save You Time, Stress, and Money.The Buzz on Motorcycle Parts New Zealand Specialists

So, get to out to one of our professionals today.CNC machining technology is promptly coming to be the centerpiece of various production processes around the globe as a straight outcome of its lots of benefits over various other techniques. In addition, the markets that manufacture bikes have hopped on board with this trend. One of the most ingenious firms are now creating their engine components and wheels making use of machining methods originally developed for motorcycle components.

On the various other hand, the results of market are the key focus of this write-up. Allow's get right into it. You may be wondering why we utilize. It is not tough to fathom the factors that caused this outcome. Since we have your attention let us describe the rationale behind this modern-day growth in the motorcycle manufacturing market.

Motorcycle Parts New Zealand Specialists Fundamentals Explained

Furthermore, you have full control over the appearance of the elements, even to the minute details. Periodically, motorcyclists might determine to beautify their ride by installing aftermarket parts or customizing the bike's makeover. As soon as once again, computer mathematical control (CNC) machining is the most functional technique. Upgrades may be of any form and style you desire.

The Definitive Guide for Motorcycle Parts New Zealand Specialists

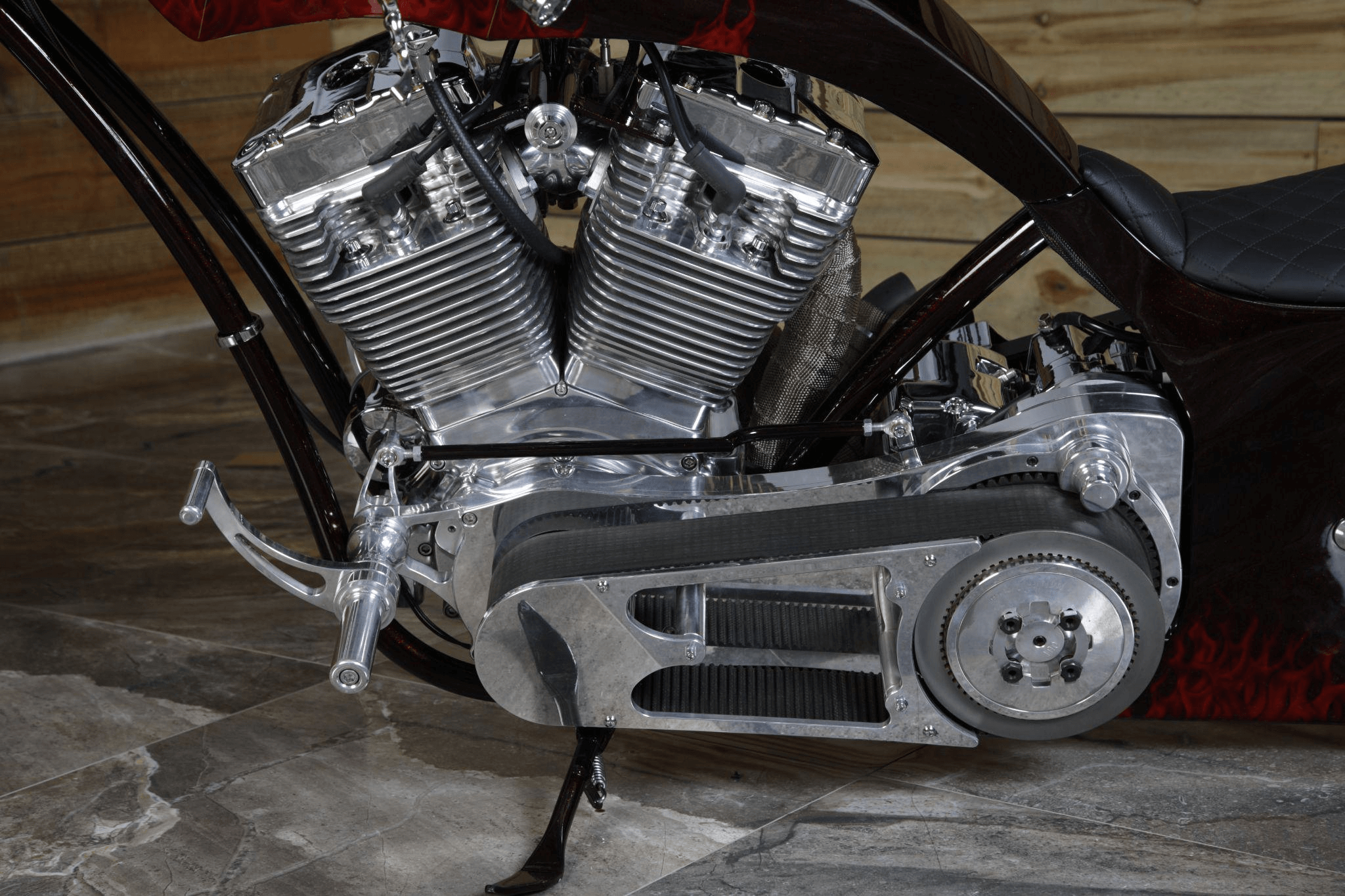

CNC machining might be utilized to make nearly all of a bike's metal and plastic elements. To proceed, we'll talk about a number of machined components for motorbikes. In comparison to those on cars, wheels on motorbikes have a tendency to be a lot more noticeable. Therefore, the bike's looks may be boosted with the appropriate modification of these wheels.When tailoring the wheels, the disks are where the emphasis should be. The majority of them are constructed of light weight aluminum. Light weight aluminum alloys are well-known for the exceptional machining capabilities that they have. Milling procedures are utilized to get the desired level of wheel modification. An additional aspect of the motorcycle that may be customized is the tires.

Motorcycle Parts New Zealand Specialists - Truths

When it concerns a car (or a motorcycle), the most important part is the engine. A number of people point to it as the "heart" of the auto. On the various other hand, the camshaft, the cylinder head, and the pistons have a tendency to be complex and call for styles with a high degree of precision.Lighting is another complex aspect of personalization. Usage just websites high-quality items, nonetheless, given that these lights are essential for the security of motorcyclists and various other browse around these guys motorists or individuals on the road, specifically in the evening. Bike headlights have three major parts: the light bulb, or light, the lens, and the real estate. Particularly, we customize the lens and the housing.

Milling procedures with a perfect coating would lead to the lenses having a reflective high quality that resembles that of a mirror. The cover, on the other hand, is not composed of breakable materials; instead, it is created out of hard polymers that can be machined right into even more intricate patterns.

Getting The Motorcycle Parts New Zealand Specialists To Work

They typically have elaborate geometries with a wide range of minute information. Motorbike manufacturers commonly cast these elements, but just for the manufacturing of bespoke components. CNC machining is the approach of selection when generating distinct pieces. Machining on 5 axes in today's world is the methods by which any kind of layout shape might be understood.Select Runsom for your personalized motorcycle parts! We have the ability to make complicated and trendy elements making your bike incomparable.

Below are a few instances of steels frequently used in bike part machining. Light weight aluminum is the primary material used by companies focusing on producing personalized motorbike elements to create the majority of these components. In the past, we would construct our engines out of actors iron. On the various other hand, aluminum is quickly becoming the material of selection, partially due to the reality that it is much more light-weight.

Zinc refers to one more metal that is really light in weight and has wonderful machining high qualities as a result of its high mechanical toughness. This material might be developed into nearly any type of form and keeps its dimensions well. Even mission-critical elements that need a high degree of precision may profit from their usage.

Unknown Facts About Motorcycle Parts New Zealand Specialists

An additional steel that sees hefty usage in the manufacturing of CNC-customized elements is magnesium. It is among the lightest metals that are currently available and has excellent machinability functions and stamina proportionate with its low weight. One of the drawbacks of magnesium is that its dirt might conveniently ignite.

Their most typical use in producing different motorbike elements is bolts, such as screws and screws. Their low vulnerability to oxidation and deterioration makes them perfect for this use.

Some Ideas on Motorcycle Parts New Zealand Specialists You Should Know

It appears that CNC transforming and milling are the foundational procedures. In addition, it requires keeping bars of product, most frequently plastic or metal, in placement and after that turning a cutting tool to eliminate areas of the product as the material is turned.

These techniques are equally vital and generate elements with high precision and consistent high quality. They are specifically: grinding, laser cutting, and exploration. The term "surface area coating" refers to post-processes after the preliminary machining phase. Motorcycle Parts New Zealand Specialists. The procedures help enhance the general top quality of the machined motorcycle components. Below are the brief introduction, pros and disadvantages of 5 surface area therapy methods.

Motorcycle Parts New Zealand Specialists Things To Know Before You Get This

Report this wiki page